Concreting is a process that requires careful preparation and precision to ensure the high quality of the resulting structure. One of the key components that guarantees the stability and correct placement of the reinforcement in the concrete are spacers. These inconspicuous but essential components help maintain the correct distance between the concrete reinforcement and the surface of the structure, thereby ensuring the correct position of the concrete and its protection against corrosion.

There is no distance like distance

Spacers can be found in a wide variety of structures, such as buildings, bridges, tunnels, roads, dams, power plants, etc. To achieve a durable and high-quality concrete structure, it is crucial to follow the correct procedures and use appropriate materials. Therefore, when reinforcing concrete structures, spacers are one of the key components and ensure the long service life and strength of the structure.

Spacers come in various designs and are most often made of concrete, plastic or steel. Steel spacers are characterized by exceptional durability, which is why they are mainly used in more complex structures where maximum strength and uncompromising stability of the reinforcement are necessary. Steel spacers can have different lengths, weights and designs. Key in construction are metal spacers of type D and spacers of type S. Both types differ primarily in their shape, which also determines the method of their use. While spacers of type D are intended mainly for horizontal reinforcement, the curvature of type S is the ideal shape for vertical reinforcement.

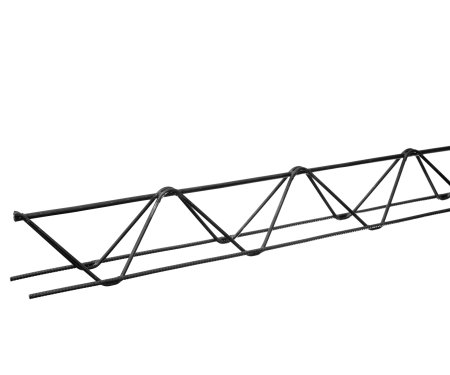

Type D spacers

D-type spacers are designed to provide a stable and firm support for horizontal reinforcement, e.g. in floor slabs or ceiling structures. Their flat base ensures good stability on the formwork. For example, in the construction of a large industrial hall, type D spacers are used to ensure an even distance between steel mats in the floors. This ensures that the concrete perfectly covers the entire reinforcement and prevents the formation of voids. In general, D-type spacers are more stable, use more material in their production and are therefore heavier and somewhat more expensive than S-type spacers.

Areas of application:

- floor slabs: when concreting floor slabs, D-type spacers are placed under the bottom layer of reinforcement to ensure proper coverage from the lower formwork.

- ceiling structures: ensure the correct position of the reinforcement before pouring concrete when concreting ceiling structures.

- prefabricated elements: in prefabricated production, D-type spacers are often used to stabilize the reinforcement during handling and transport.

Due to their shape, D-type spacers provide stable and firm support for horizontal reinforcement

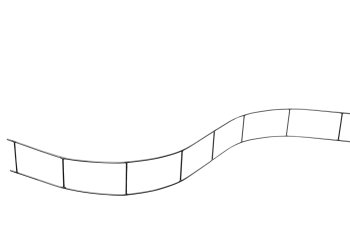

Type S spacers

S-type spacers are characterized by their characteristic curved shape resembling the letter "S". This shape allows them to hold vertical reinforcement stably, for example in walls, columns or piers. The curvature ensures that the element holds firmly on the reinforcing bars and prevents it from slipping during concreting, when the structure is exposed to lateral pressures or vibrations during concrete pouring. For example, spacers are an ideal choice when building an arch bridge, where they fix the reinforcement in curved parts of the bridge deck and ensure that all gaps are filled with concrete correctly. Due to their shape and method of use, S-type spacers are therefore lighter and therefore somewhat cheaper.

Areas of application:

- walls: When concreting walls, S-type spacers are attached to the vertical reinforcement, ensuring proper cover from the formwork.

- columns and pillars: In column and pillar constructions, these elements are used to maintain the correct distance between the reinforcement and the outer surface of the concrete.

- retaining walls: When constructing retaining walls, S-type spacers are used to ensure proper cover of the reinforcement that is exposed to earth pressure.

S-type spacers have a characteristic curved shape resembling the letter "S"

The selection of the correct type of spacer depends on the specific application and orientation of the reinforcement. Using the wrong type can lead to insufficient reinforcement coverage, its displacement during concreting and ultimately to a reduction in the durability and safety of the concrete structure. It is therefore important to pay due attention to the selection and correct use of spacers when planning and executing concrete works.

Interestingly, Nordic countries, especially Scandinavian ones, generally prefer to use D-type spacers, while in Germany, the Czech Republic, and even to the east of us, type S is preferred. This is a habit, not a general rule. In general, both types of spacers are used in all these countries.

TIP: In our product portfolio you will find spacers of type S and type D as well as our new product spacers of type DB. We also recommend visiting our e-shop, where you can easily purchase the necessary products online.

Do you have any questions about our products? Then do not hesitate to contact us, or visit the FAQ section, which we are constantly updating.